XCMG's new 80-ton crane is finally coming!

Publication Date: 2019-07-31

Since 2016, the 80-ton class has been gradually popular, and the attention to this day is still only increasing. In the hands of many bosses with 25-ton cranes, after laying a solid profit base, in order to enhance the company's development in the larger field and local hoisting influence, 80 tons is undoubtedly a must.

As a customer's indispensable tonnage in the development of large tonnage, XCMG is also "stretching the brain" to create this "enrich weapon" - XCT80L5.

Following the classic look of the G-generation products that everyone is already familiar with, the yellow body is embellished with the latest technology blue logo of 2019. Fully covered walkway, aluminum alloy profile, increased non-slip in the second direction, better anti-slip effect, independent wheel package, rich in layers.

The whole machine is 15 meters long, 4 bridge body, and the front and rear of the tires are arranged 8 times.

The XCT80L5 is the only crane in the industry that uses the “K” shaped leg (commonly known as the “pendulum leg”) in this class. It is also a two-stage telescopic control. The operation method is to first swing out the legs and then extend the second section. After stretching, the first visual feeling is solid. Indeed, the K-type leg has a higher hoisting capacity in the front and side of the front than the H-leg with the fifth leg.

5 section single arm head design, double cylinder rope row telescopic mode, main arm full extension total length 50.5 meters, standard 17.5 meters fixed jib, more than 30m bridge construction, plant equipment installation and other high-frequency working conditions leading more than 10%, homework The efficiency industry is optimal. The total weight of the counterweight is 16 tons.

Automatic working condition planning technology: The system interface inputs height, weight and amplitude parameters, and automatically recommends the optimal working condition.

New energy-saving hydraulic system with high efficiency, strong durability and better micro-motion (lifting: 2.5m/min, revolving: 0.1°/s)

The industry's only tonnage-class product is the only Class G off-road chassis, with the front foot plate 450mm off the ground.

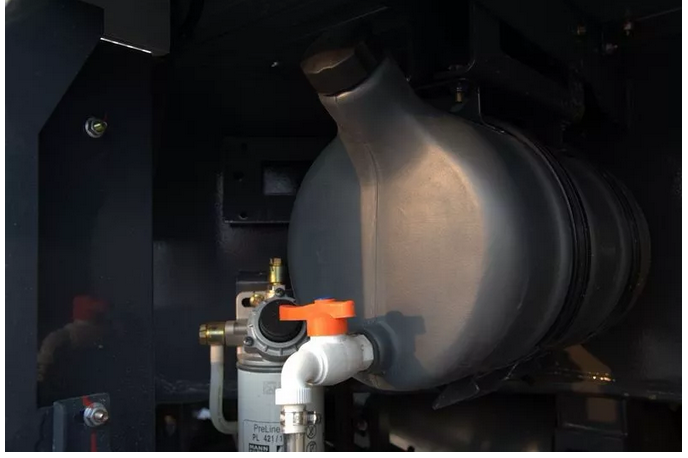

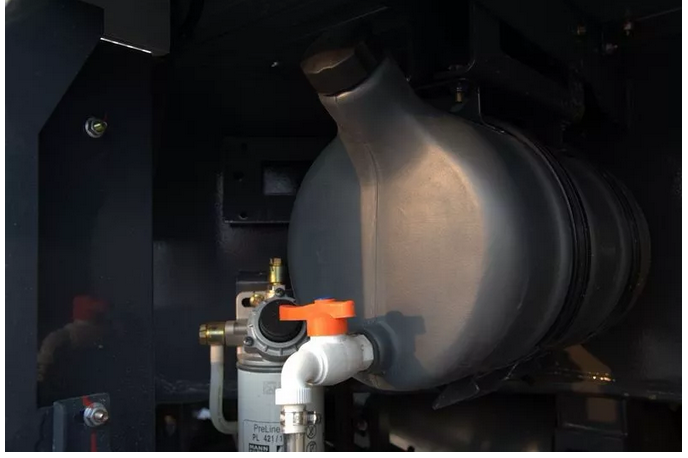

Low-speed high-torque powertrain, MC11.40 high-powered engine of German MAN technology platform, rated power 297kw, output torque up to 1900Nm, maximum climbing capacity 47%, maximum speed 90km/h.

High load-bearing and high-speed ratio axles and high-grade tires. Front tire specifications: 385/95R25 (front axle) with stronger bearing capacity and better tire wear resistance.

10 speed gearbox with synchronizer, high load-bearing speed ratio axle, taking into account the low-speed climbing performance and high-speed transition performance of the vehicle; assisting shifting, even if the system fails, normal mechanical shifting can be performed.

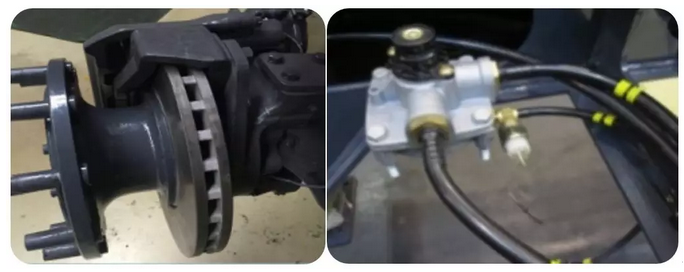

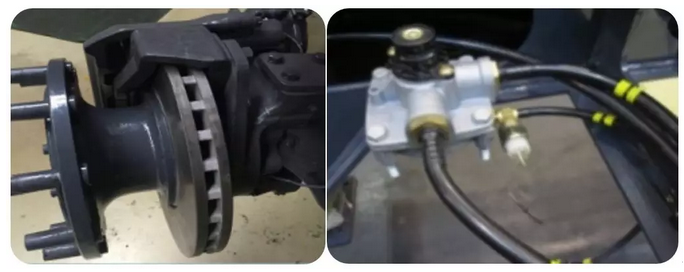

The principle of the G generation brake system, the front axle is equipped with a disc brake with a diameter of 25 inches. It has a larger braking torque, better stability, less heat, high system pressure, and high reliability components such as German imported VOSS pipe joints. Responsive, fast response time and safer braking.

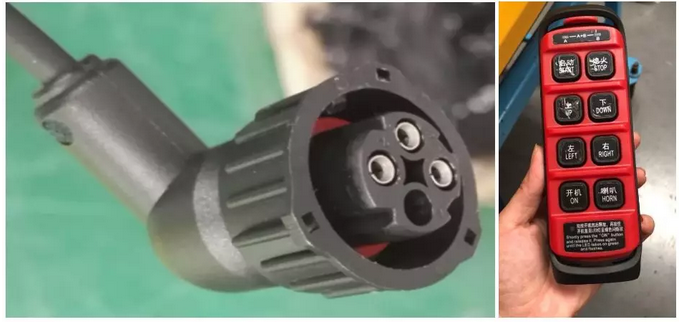

All-round anti-skid board, washing water tank, tire bolt anti-loose indicator cap, standard reversing image; high-gloss LED leg lighting; large-field winch monitoring mirror; jib double-tip pin design; integrated casting weight The logo, counterweight wireless remote control, the weight installation operation is more convenient, and the hook is easy to wear the rope system.

The main air suspension seat, automatic height adjustment, double-drive double seat, can be expanded into a simple sleeper; the top window is upgraded to a double-layer sunshade with full shading and semi-shading effects; the rear window adds sunshade and increases electric heating. Functional seat cushion.

As a customer's indispensable tonnage in the development of large tonnage, XCMG is also "stretching the brain" to create this "enrich weapon" - XCT80L5.

Exterior

Following the classic look of the G-generation products that everyone is already familiar with, the yellow body is embellished with the latest technology blue logo of 2019. Fully covered walkway, aluminum alloy profile, increased non-slip in the second direction, better anti-slip effect, independent wheel package, rich in layers.

The whole machine is 15 meters long, 4 bridge body, and the front and rear of the tires are arranged 8 times.

The XCT80L5 is the only crane in the industry that uses the “K” shaped leg (commonly known as the “pendulum leg”) in this class. It is also a two-stage telescopic control. The operation method is to first swing out the legs and then extend the second section. After stretching, the first visual feeling is solid. Indeed, the K-type leg has a higher hoisting capacity in the front and side of the front than the H-leg with the fifth leg.

5 section single arm head design, double cylinder rope row telescopic mode, main arm full extension total length 50.5 meters, standard 17.5 meters fixed jib, more than 30m bridge construction, plant equipment installation and other high-frequency working conditions leading more than 10%, homework The efficiency industry is optimal. The total weight of the counterweight is 16 tons.

Automatic working condition planning technology: The system interface inputs height, weight and amplitude parameters, and automatically recommends the optimal working condition.

New energy-saving hydraulic system with high efficiency, strong durability and better micro-motion (lifting: 2.5m/min, revolving: 0.1°/s)

The industry's only tonnage-class product is the only Class G off-road chassis, with the front foot plate 450mm off the ground.

Low-speed high-torque powertrain, MC11.40 high-powered engine of German MAN technology platform, rated power 297kw, output torque up to 1900Nm, maximum climbing capacity 47%, maximum speed 90km/h.

High load-bearing and high-speed ratio axles and high-grade tires. Front tire specifications: 385/95R25 (front axle) with stronger bearing capacity and better tire wear resistance.

10 speed gearbox with synchronizer, high load-bearing speed ratio axle, taking into account the low-speed climbing performance and high-speed transition performance of the vehicle; assisting shifting, even if the system fails, normal mechanical shifting can be performed.

The principle of the G generation brake system, the front axle is equipped with a disc brake with a diameter of 25 inches. It has a larger braking torque, better stability, less heat, high system pressure, and high reliability components such as German imported VOSS pipe joints. Responsive, fast response time and safer braking.

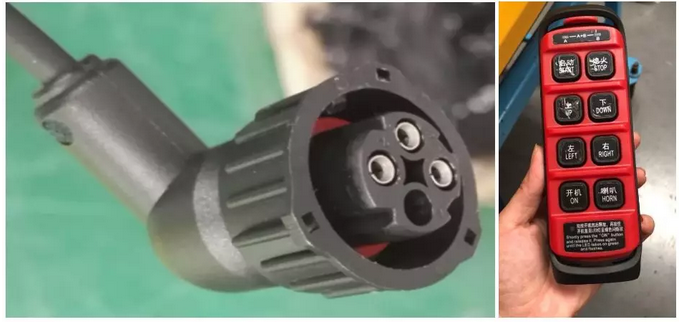

All-round anti-skid board, washing water tank, tire bolt anti-loose indicator cap, standard reversing image; high-gloss LED leg lighting; large-field winch monitoring mirror; jib double-tip pin design; integrated casting weight The logo, counterweight wireless remote control, the weight installation operation is more convenient, and the hook is easy to wear the rope system.

The main air suspension seat, automatic height adjustment, double-drive double seat, can be expanded into a simple sleeper; the top window is upgraded to a double-layer sunshade with full shading and semi-shading effects; the rear window adds sunshade and increases electric heating. Functional seat cushion.